Thermoplastic Silicone Elastomers

Polymer material systems with the characteristics of silicone

NEFA® MB P materials are thermoplastic elastomers based on polydimethylsiloxane-polyurea copolymers. With these systems, urea hard segments form thermally reversible network points and give the copolymers dimensional stability, with the polydimethylsiloxane sequences acting as soft segments. Thermoplastic elastomers of the product group NEFA® MB P combine the properties of conventional silicone elastomers with the advantage of thermoplastic workability.

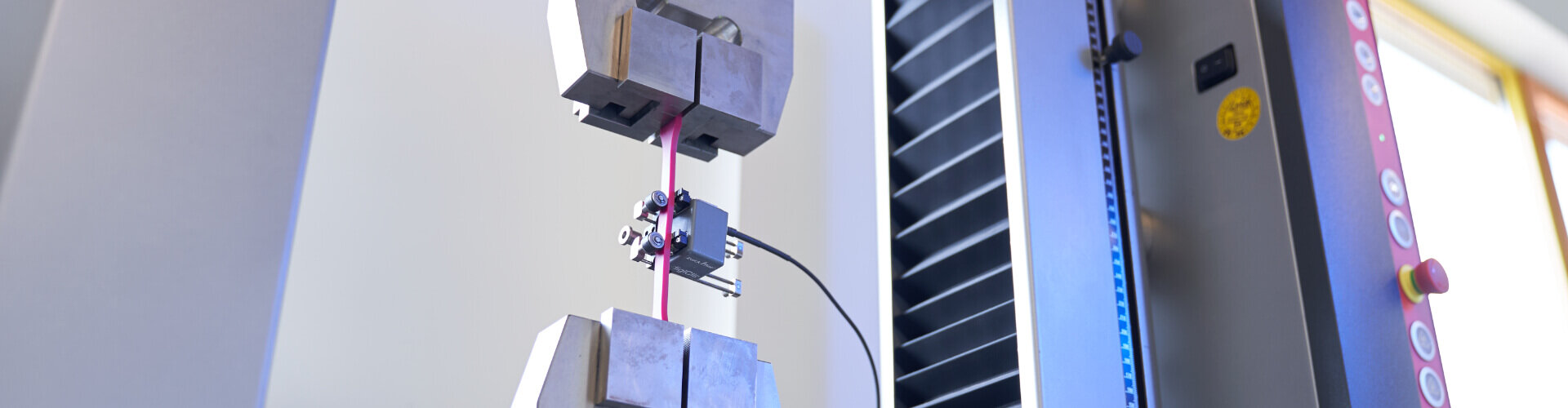

Polymer materials in the NEFA® MB P group represent a separate class of thermoplastic elastomers which, in their properties profile, are an interesting complement to the existing spectrum of TPEs. Unmodified basic polymers in this product group can be produced for individual customers in a hardness range of Shore A 35 – Shore A 80. The tensile strength of the materials is between 1.5 and 6 Mpa, depending on the hard segment level and the hardness. As a complement to conventionally networking silicone elastomers, NEFA® MB P materials are characterised by the following properties in particular:

- high transparency

- high UV resistance

- high mechanical strength in comparison with silicone elastomers

- thermoplastic workability